paint dolly test|dolly preparation adhesive testing : factory Portable pull-off adhesion testers, like the PosiTest AT, measure the force required to pull a specified diameter of coating away from its substrate. This . See more Chopin. Condomínio de apartamentos construído em 1956 (há 68 anos). O condomínio residencial Chopin é composto por uma torre única.com 1 e 4 dormitórios e 1 e 3 vagas. .

{plog:ftitle_list}

Resultado da 20 de abr. de 2023 · CASINO EVASION : MODE D'EMPLOI. Rédigé le 20/04/2023. Partager

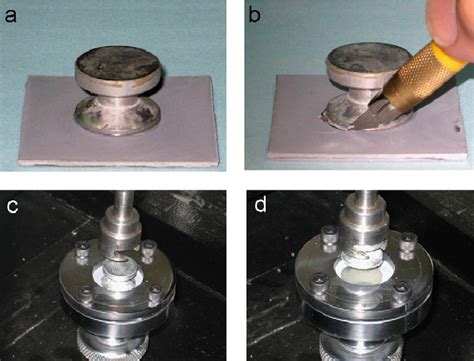

This articles discusses the process of dolly preparation to ensure a strong bond at the dolly-adhesive interface and its importance in maximizing repeatability of pull-off adhesion testing. See morePortable pull-off adhesion testers, like the PosiTest AT, measure the force required to pull a specified diameter of coating away from its substrate. This . See moreDollies for pull-off adhesion testers are constructed of a wide variety of metals including aluminum, carbon steel and stainless . See moreThe following dolly preparation recommendation was optimized for the Annex A5 adhesion tester under study using the results of an investigation of commonly accepted methods and subsequent experimental results.1 A detailed experiment was developed to verify and summarize the results of tests and comparisons previously conducted . See more

It is important to note that the development of hypotheses, and the selection and elimination of factors was based on several previous tests, comparisons and experiments. Some of the eliminated factors with related test results are briefly outlined below. The effect of shot blasting dollies was compared to end milling. Three epoxies from . See moreThe tensile pull-off method for adhesion testing, as outlined in ASTM D 4541 and similarly in BS EN ISO 4624, involves gluing a test dolly to the coated surface and then pulling the dolly by .

The pull-off test is performed by securing a loading fixture, such as a dolly or stud, to the surface of the coating being tested with a glue. A testing apparatus is attached to the loading fixture and aligned to apply tension to the .ISO 4624:2016 specifies three methods (i.e. one dolly or two dollies on a painted panel and two dollies, one as painted substrate) for determining the adhesion by carrying out a pull-off test on a single coating or a multi-coat system of paint, varnish or related product. These test methods have been found useful in comparing the adhesion . Adhesion Test: This test is used to determine the adhesion strength of different types of paints and coatings applied on different metal surfaces.At Divine M.

The tensile pull-off method for adhesion testing, as outlined in ASTM D 4541 and similarly in BS EN ISO 4624, involves gluing a test dolly to the coated surface and then pulling the dolly by exerting a force perpendicular to the surface in .A test dolly is bonded to the coating using an adhesive. The Elcometer 106 adhesion tester houses a spring arrangement which applies a lift force to the dolly as the tension is increased. When the coating is pulled off the surface, an indicator on the scale shows the numerical value of adhesion strength expressed in terms of the force per unit .

the dolly face and surface, to determine the failure mode. For a valid pull test, the coating must cover at least half of the area of the dolly face. If the glue fails, and no coating is present on the dolly, or it covers less than half of the dolly face area, the .In the paint and coating industries, paint adhesion testing is often used to determine if the paint or coating will adhere properly to the substrates to which they are applied. Several tests measure the resistance of paints and coatings from substrates: cross-cut test, scrape adhesion, pull-off test , and others.2 test piece 3 dolly 4 ball-and-socket sliding joint 5 support (suitably designed to allow for joint assembly) 6 ball-and-socket sliding joint Figure 2 — Example of a suitable test apparatus for the one-dolly method described in 8.4.2 (method B) 4.2 Test dollies, each consisting of a steel or aluminium cylindrical-faced testing body, specifically

A test was performed using an aluminum surface primer in an attempt to maximize the dolly adhesive bond. The surface primer tested was Henkel Alodine 1132 which came highly recommended as a military accepted conversion coating. The test used an equal number of dollies of different abrasion methods includingPositioning a dolly over a ridge or weld is inappropriate as the adhesive test requires that the dolly is removed perpendicularly to the substrate. There are “self- alignment” methods to ensure that the dolly is pulled off the surface of the substrate. However, unless the dolly and the actuator are perpendicular to the substrate the actual .Pull-Off Test: This method assesses the adhesion of either one or multiple coatings on a smooth surface by applying tensile stress (rather than shear stress measured in the previous two tests) from a dolly to the surface.The load is slowly increased until the dolly along with the adhesive layers is removed. This procedure can also be administered on-site and provides quantitative .

ASTM D4541 and BS EN ISO 16276-1 describe several different test apparatus; however, the basic approach of gluing a test dolly to the coated surface and then exerting a perpendicular force to the surface in an effort to remove both the dolly and the coating from the substrate is common to all these standards. TEST METHODDetermination of coatings adhesion by pull-off method ASTM D4541Upon completion of a pull-off test, the dolly and coated surface should be examined. In addition to pull-off force, many National and International standards such as ASTM D4541 and ISO 4624 require the nature of the fracture to be recorded. Cohesive fracture: fracture occurs within a coating layer (same coating on dolly face and coated .An adhesion test dolly is bonded to the coating using an adhesive. The Elcometer 106 adhesion tester houses a spring arrangement which applies a lift force to the dolly as the tension is increased. When the coating is pulled off the surface, an indicator on the scale shows the numerical value of adhesion expressed in terms of the force per unit .

When higher pull-off strengths are required, the PosiTest AT can be used with custom sized dollies to attain higher pull-off strengths.For example, a 14 mm dolly provides double the pull-off strength of a 20 mm dolly. With 14 mm .

loads to the test dolly or fracturing the substrate, all of which affect test results. Use of a sharp and properly sized cutting instrument is critical to minimizing altered results. ACCEPTABLE ADHESION TEST RESULTS . Acceptable adhesion test results are dependent upon many variables as discussed previously. When testing coatings on The main purpose of dolly adhesion test is to ensure that the coating is firmly bonded to the substrate to provide long-lasting coating protection and to ensure that the coating will not peel, flake, or crack during use. Dolly .

This 20mm dolly was applied adjacent the coating test square. The adhesion pull-off strength of the dolly glued directly to the concrete substrate should be a good representation of the tensile strength of the concrete being tested. . When To Paint Your House - 5 Useful Tips For Interior Painting 10 Ideas For Your Garage Makeover Surviving .Raven Lining Systems - Home - Raven Lining Systems Test method. All tests are done in accordance with the ASTM D4541 and BS EN ISO 4624 standards. For these test methods, we glue a standardised component (the ‘dolly’) to the coating and let the adhesive cure for 24 hours. There is a selection of dollies with different diameters. If necessary, we cut through the top coat around the dolly.

dolly pull off testing

The test area is then brushed diagonally five times in each direction to remove any loose film finish particles. A special tape for testing adhesion is then firmly applied over the cross-hatch test area and removed quickly by pulling the tape back off of the test area to reveal the amount of coating lifted off by the test tape. The cross .The tensile pull-off method for adhesion testing, as outlined in ASTM D 4541 and similarly in BS EN ISO 4624, involves gluing a test dolly to the coated surface and then pulling the dolly by exerting a force perpendicular to the surface in an effort to .ASTM D 4541 Type V - In the same way that an Elcometer 106 exerts a mechanical force to pull the dolly off the coated surface, gauges such as the Elcometer 506 and the Elcometer 510 exert a force hydraulically on the dolly to pull it off the surface. Both of these gauges enable a much smoother application of the force as specified in the Standards.

The Dolly Plugs are for use with the Dollies supplied with the Adhesion Tester to stop the Turbo Fuse Adhesive going down the Dolly hole. [email protected]; . By entering your email address above, you're consenting for Paint Test Equipment to send our newsletters, offers and promotions directly to your inbox. .

New and updated edition.When testing coating adhesion using a pull-off adhesion tester, there are a range of dolly sizes and gauge types to choose from; and .ISO 4624 adhesion testing is a specific pull-off procedure that evaluates the durability of protective coatings. The test is conducted by gluing a dolly to a metal surface with a protective coating and applying an external force to the dolly. Remove the coating by pulling the dolly at a perpendicular angle and assess the results.Record the results of the test and compare them to the specifications for the coating or adhesive. If the results fall within the acceptable range, the coating or adhesive is considered to have good adhesion. Paint inspector is testing pull-off adhesion (dolly) test for coating.

wire thickness measurement

xrf thickness measurement

webJogo De Faca Do Rotor Da Ensiladeira Jf 40 (4x1) O frete grátis está sujeito ao peso, preço e distância do envio. Frete grátis no dia Compre Ensiladeira Jf 40 Ferramentas .

paint dolly test|dolly preparation adhesive testing